Columbia University, Seasonal Air Supported Structure

A translucent membrane and cable grid structure held up by slight positive air pressure provides a heated indoor environment that supports numerous sports programs during winter months.

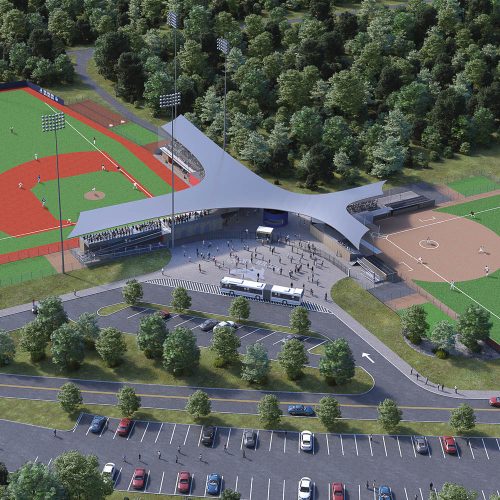

Columbia University’s Department of Intercollegiate Athletics and Physical Education needed a space for its varsity (NCAA Division 1) and recreational sports teams to train during the winter months. Rafael Viñoly Architects proposed an innovative solution consisting of a new artificial turf field that could be covered seasonally by a heated air-supported membrane structure. Installed at Rocco B Commisso Soccer Field at the Baker Sports Complex, the 375-foot-long by 240-foot-wide by 73-foot-tall structure, fabricated by Arizon Structures, is the largest air supported structure ever built in New York City.

The seasonal air-supported structure provides Columbia and the local community a heated and illuminated indoor environment that supports numerous programs during winter months, including football, soccer, baseball, softball, field hockey, lacrosse, golf, archery, intramurals, and club sports.

The translucent membrane and cable grid structure is anchored to a continuous structural grade beam below the surface of the playing field, which is covered with removable turf trays during the spring, summer, and fall seasons to allow the artificial turf field to be used throughout the year. The membrane is held up by a slight positive air pressure created by air handling units located adjacent to the structure.

To guard against the potential for failure and to satisfy stringent FM Global insurance requirements, the double skin cable-restrained, air-supported membrane structure included a number of redundant design features. First, the structure was designed to accommodate a 30 psf snow load with the structure capable of supporting the full building design snow load and dead load without the use of snow melting or other snow removal methods, such as manual snow removal off the roof. This ensures that the structure will not fail during a significant snow event, when the University facilities team may be unable to access the structure for maintenance. For additional protection, the structure also included a triple-redundant inflation system including one primary heating and inflation unit, one standby heating and inflation unit, and natural gas-powered back-up generators to provide a completely redundant auxiliary inflation system.